02:09 Also, the lower control limit is always 0.02:04 Well, for the first data point, there is no previous data point, so.02:01 between the current data point and the previous data point point.01:58 Remember, the moving range is the absolute value of the difference.01:53 First, there’s no data point that corresponds with the first.01:50 There are a couple of interesting points about the moving range chart.01:46 This makes it easier to see the impact of a special cause.01:44 they can be lined up one above the other.

.jpg)

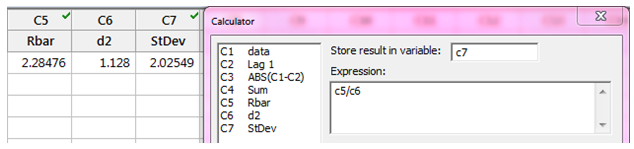

00:38 We also want to be using this second chart, the moving range chart.00:34 Well the control limits we will calculate will help to control the process.00:29 It might be the dimension on a product, or the cycle time for a process step.00:25 This is normally the product or process parameter that we're trying to control.00:21 The individual chart is the chart of the data values that have been measured.00:17 I-MR is a pair of control charts that work together.00:12 The I-MR Chart stands for Individual and Moving Range.00:06 Let's take a close look at the first of our variable data control charts,.Be sure to use the subgroup sample size of 1 when selecting the d2 and d4 constant values.The LCL for the Moving Range is always zero.Take appropriate actions to remove special causes or to center your data within the customer spec limits.Plot the data points, the Mean and the control limits.Now calculate the control limits for the Individual data points.If the Moving Range plot shows an out of control condition, it must be corrected before proceeding to the Individual plot, since that plot relies on the mean of the Moving Range in its control limit calculations.The lower control limit is always zero for this chart. Calculate the upper control limits for the Moving Range plot.Calculate the Mean for the Moving Range data and the Individuals data.In an adjacent column, calculate the Moving Range for each data point.Measure the attribute and record the data in a column in Excel.Within Minitab, control charts are created by using the “Stat” pull down menu, then selecting “Control Charts.” Within the Control Charts window, select “Variable Charts for Individuals” and then finally select “I-MR.” In the Minitab I-MR Chart panel, you will need to select the data column with your data.

I-MR Charts can be created in Microsoft Excel or in Minitab. (For this reason, there is no Moving Range value for the first point since there is no pervious data point. The Moving Range chart plots the absolute value of the difference between the current data point and the previous data point. The Individual chart plots the data value as measured.

This aids in the recognition of special cause occurrences. These are normally aligned so that the Individual chart is directly above the Moving Range chart. The I-MR is comprised of a pair of control charts. It is also frequently used with low volume processes that complete one item at a time. It is often used with critical characteristics that are identified on design documentation. Use the I-MR chart when seeking to control a product or process variable parameter. It can be easily created in either Microsoft Excel or Minitab. The I-MR chart (Individuals and Moving Range) is the variable data control chart to be used when each item is processed uniquely and therefore a subgroup sample size of one is appropriate.

0 kommentar(er)

0 kommentar(er)